Symco Group has a customer who has two Bell and Howell ten station Enduro Inserters with Jet Vision cameras, high cap feeders and on edge conveyors for immediate sale.

If you have interest in one or both of the Bell and Howell Enduro Inserters, please contact Symco Group at 800-878-8002 or email us at info@symcogroup.com.

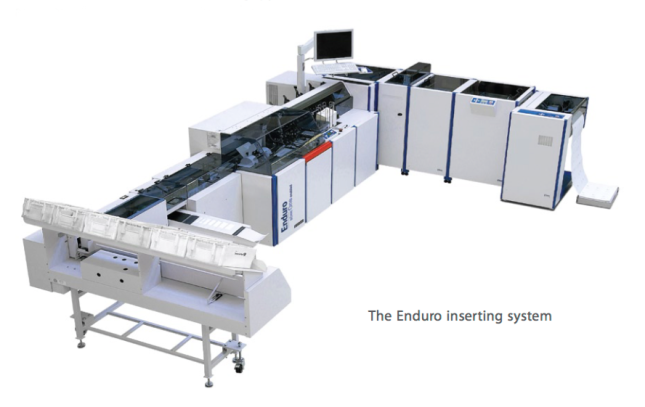

Bell and Howell Enduro Overview:

The Enduro inserting system will operate at speeds up to 11,000 envelopes per hour, depending on the configuration. These processing speeds make the Enduro inserting system a formidable solution for operations that process high volumes of one- to multiple- page, statement-type jobs in any environment where numerous applications are run on a regular basis.

Based on BÖWE BELL + HOWELL’s industry-renowned gripper-arm inserting technology and powered by the KOMPOS control system, the Enduro inserting system represents a new evolution in inserting technology.

Thanks to the integrated KOMPOS microprocessor and its plug-and-play design, the Enduro inserting system bring a new level of modularity to BÖWE BELL + HOWELL’s proven gripper-arm inserting technology. This opens the door to a broad and diverse range of add-on modules that can easily be integrated with the base system, including BÖWE BELL + HOWELL’s new line of dual-channel and cut-sheet feeders.

These modules, each with their own KOMPOS controller, communicate continously with the operating system to ensure complete mail piece integrity while improving performance levels by up to 40 percent on certain applications.

The Enduro inserting system features an integrated, intelligent learning technology known as Smart GRIP (Grip Remember Inform & Pull). With Smart GRIP, operators can activate a “teach” command through the user interface. In this mode, the gripper arm “reads” an insert, “remembers” the reference values and “reports” the thickness of the enclosures to the operating system.

As a job proceeds, each of the enclosures is compared to the stored values, and any processing errors—such as double pulls or misses are immediately identified. Since the operator can set the job to automatically bypass the mailpiece, use a backup enclosure feeeders, or stop for inspection integrity is enhanced and throughput maximized.

In addition to Smart GRIP, the Enduro inserting system offers pneumatic gripper arms. The pneumatic gripper arms, which can replace or be used in conjunction with the standard gripper arms, greatly increase the Enduro’s performance when processing difficult materials.

The Enduro inserting system may be configured with up to 24 insert stations. All enclosure feeders can be pneumatic, standard or any combination of both.

Additional improvements to the Enduro inserting system include:

- Intelligent tracking throughout the document path

- High-capacity envelope loader and high-capacity insert feeders

- A redesigned insertion station

- A new operating system and user interface

- A high-volume, on-edge output conveyor

One system, multiple uses

The Enduro inserting system is built on BÖWE BELL + HOWELL’s modular design philosophy. This unique approach allows each system to be configured based on a customer’s specific requirements while affording the flexibility to add new capabilities as those needs evolve.

There are currently more than 100 paper-handling modules that can interface with the Enduro inserting system, ranging from roll feeders and continuous-form cutters to sheet feeders and heavy-duty folders. This multi-tool approach offers a greater freedom to process a growing number of jobs and enclosures while protecting their initial investments in technology.

Enhanced document integrity

To supplement the Enduro system checks for document tracking and integrity, BÖWE BELL + HOWELL’s VEKtor reading system can be added throughout the inserter. With VEKtor in place, barcodes can be read at the feeder and inserts verified in the hopper to ensure everything matches before continuing through the system. With VEKtor any code symbology is supported including the Intelligent Mail Barcode (iMB).

Highlights

- Smart GRIP technology immediately identifies problem mailpieces

- Pneumatic gripper arms increase ability to process difficult materials

- Improved tracking of each mailpiece

- Numerous add-on modules seamlessly work with the inserter

Features and specifications

- Acceptable envelope sizes

- Minimum—6” x 3.5” (152 mm x 89 mm)

- Maximum—10”x 6.25” (254 mm x 159 mm)

- Flap depth—1” to 2.31” (25 mm x 59 mm)

- Acceptable insert sizes

- Minimum—5.5” x 3” (140 mm x 76 mm)

- Maximum—9.5” x 6” (241 mm x 152 mm)

- Maximum thickness—0.125” (3mm)

- Input Processing Options

- Sheet Feeders—591, 598

- Cutters—310, 310 Stream, 380 Stream, 5410

- Reading—2/5-I, 3/9, Code128, ECC200, OCR, Intelligent Mail barcode

- Multi-channel input/matching capability

- PCS input channels

- Fold Options (Z, Half, Double Parallel and Letter)

- Delivery Options

- Envelope Turnover

- Metering (fixed and variable weights)

- Diverting

- Envelope marking

- High capacity envelope feeder option

- Extended and on-edge conveyor options

- Ink-jet printing

- Envelope window reading (barcode, 2D and OCR)